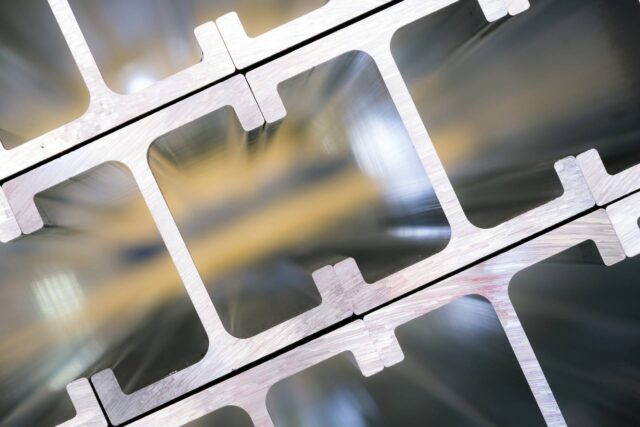

Due to its principal alloying elements, copper and zinc, 7075 extruded aluminum is considered to be the market available strongest aluminum alloy. The 7075 T6’s normal strength is found to be higher than that of other mild steels.

Additionally, the machinability, corrosion resistance, and anodizing response of 7075 extruded aluminum are all evaluated as good to medium. However, unlike 2024, it is not believed to be weldable. Spacecraft, missiles, aircraft, and other defense-related applications extensively use it.

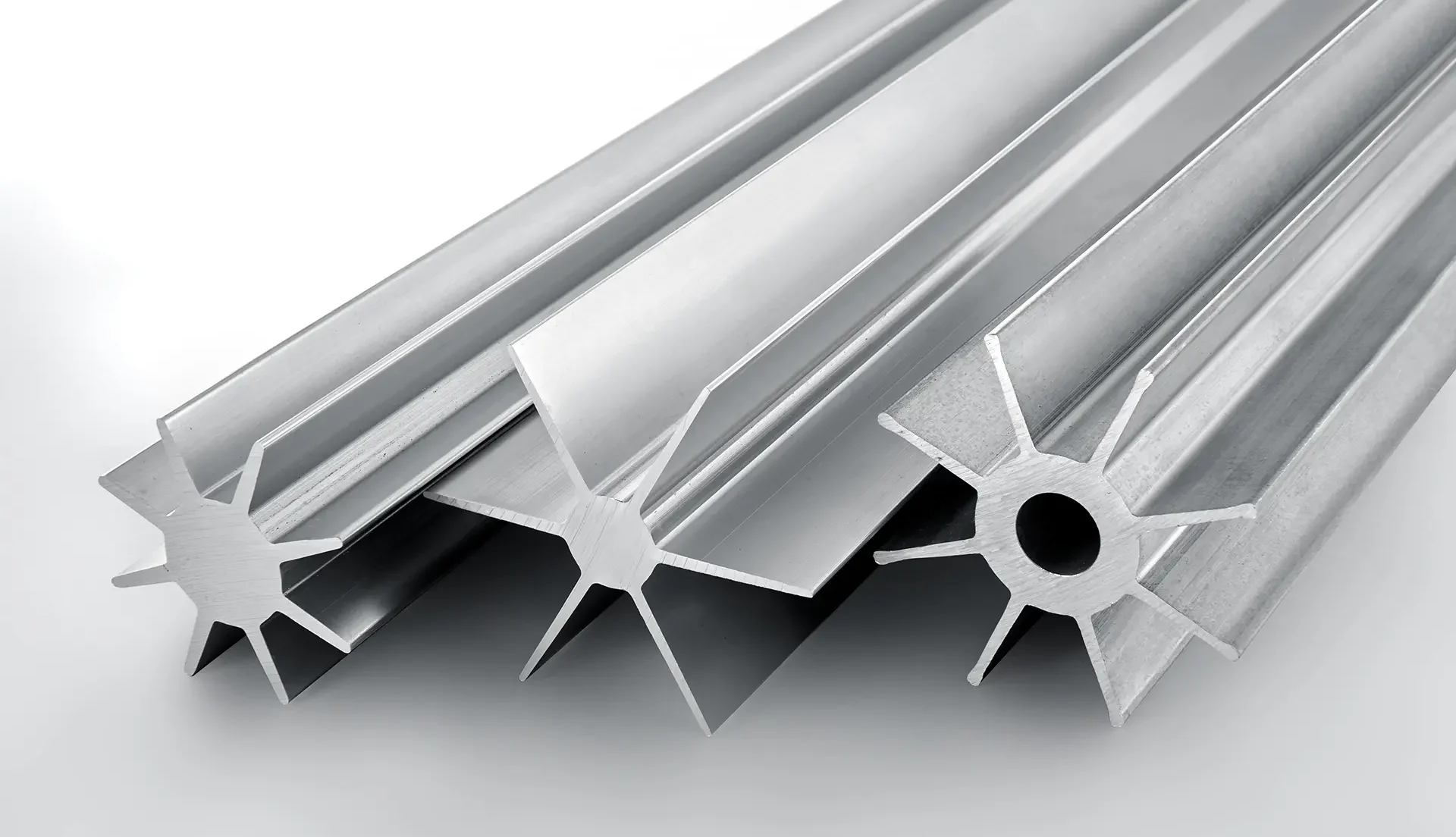

The strongest alloy of aluminum, 7075 extruded aluminum, is a cold-wrought metal that is lighter and just as durable as some products made of low-grade steel. The primary alloying elements in 7075 extruded aluminum are zinc and copper. Magnesium, iron, silicon, manganese, and other elements are listed in decreasing order of amount.

Compared to other strong materials like steel, the 7075 extruded aluminum offers higher resistance to corrosion and stress fracture. Because of its potent anodizing reaction, 7075 extruded aluminum resists galvanic corrosion, which is an issue. Thought to be a poor material for welding, it can nonetheless be connected via resistance welding.

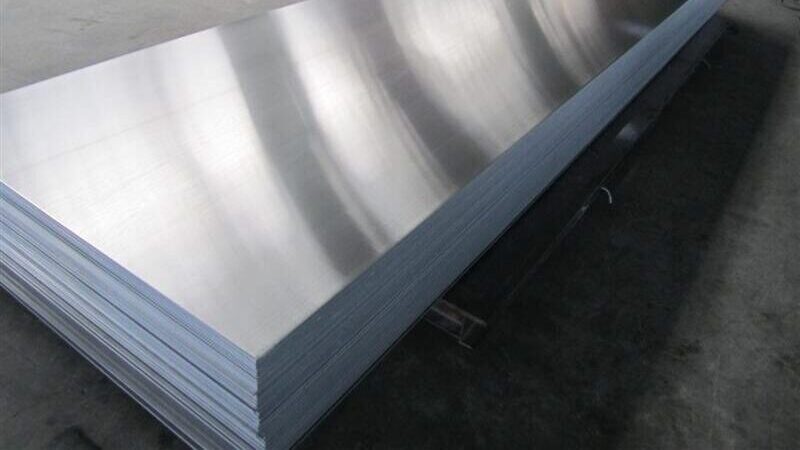

Because of their well-balanced attributes, sheets and plates made from 7075 extruded aluminum are widely used in products where strength, corrosion resistance, and high stress-reduction characteristics are crucial. Numerous T6, T73, and T76 tempers are very typically supplied in addition to the annealed form of extruded aluminum 7075.

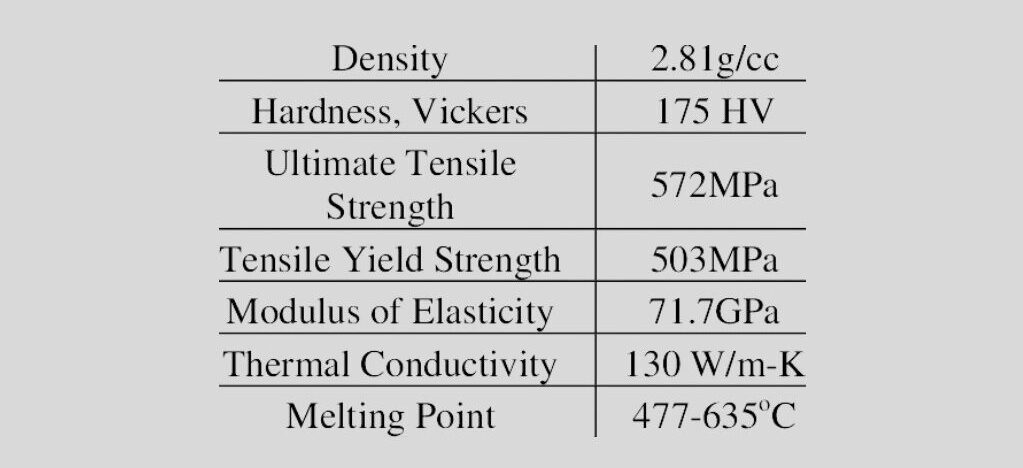

Physical Properties of 7075

Aluminum, Zinc, Magnesium, Chromium and Copper make up 7075 aluminum in the proportion of 90.0%, 5.6%, 2.5%, 0.23%, and 1.6%, albeit these percentages nominally change depending on manufacturing variables.

It possesses a low density, whose value is 2.81 gram per cubic centimeter or 0.102 pounds per cubic inch. Given its strength, one of the best aluminum alloys is 7075, which is useful in high-stress circumstances.

Although the 7075 aluminum’s susceptibility to corrosion is increased by the presence of copper, this trade-off is necessary to produce a material that is both robust and usable.

The strength of the 7075 aluminum alloy can be increased further by a procedure known as heat-treatment. The other name of this process is “tempering”. Using increased amount of heat in this process, usually between 300 and 500 degrees Celsius can either create or break a material.

This huge amount of heat can also change the crystal structure of the metal and enhance the metal’s general mechanical properties. It is crucial to note that different values and properties are imparted to a metal even though 7075-T6 comes with a standard temper value.

Mechanical Properties of 7075

The shear modulus and elasticity modulus of a material provide a measure of its resistance to deformation. The shear modulus of 7075 aluminum is 26.9 GPa (3900 ksi) while the modulus of elasticity is 71.7 GPa (10,400 ksi). This alloy works well for situations where a strong-yet-light metal is required since it resists deformation effectively.

503 MPa tensile yield strength possessed by 7075 aluminum alloy, which is also equivalent to 83 thousand psi. This value exhibits that 707 aluminum does not revert to its original shape once it crosses the limit of 503 MPa of stress.

This figure demonstrates the enormous advantages of making alloys using aluminum as a constituent. It also exhibits the selection of 7075 as an obvious choice for various components used for structuring.

A 7075 aluminum alloy’s fatigue strength is 159 MPa (23,000 psi). The fact that this figure was computed utilizing five hundred million cycles of uninterrupted, recurring loading only serves to highlight how, given enough time and modest forces, an alloy this strong can be broken.

The 7075 aluminum alloy exhibits a shear strength of 331 MPa. Given its low density, the ultimate tensile strength of 7075 aluminum is an impressively high 572 MPa (83000 psi).

Key Points

- One of the lightest and strongest aluminum alloys is 7075 extruded aluminum, which is as strong as some low-grade steels. It is also one of the strongest alloys of aluminum. As a result, 7075 aluminum extrusions provide stronger and longer-lasting properties in use.

- High strength, anode responsiveness, and outstanding mechanical characteristics characterize extruded aluminum alloy 7075. Aluminum 7075 extruded is required for aerospace constructions and other high-stress structural elements like upper and lower wing panels.

- Due to their remarkable durability, great corrosion resistance, and high strength, the 7075 aluminum extrusions are an ideal choice for several demanding applications, including marine, aerospace, and automotive.

Applications of 7075

7075 extruded aluminum is ideal for marine and automotive applications. In goods where strength is crucial, such as bike frames, hang glider airframes, and rock climbing equipment, 7075 extruded aluminum is widely employed.

In addition, precision weapons like the French PGM Precision Arms and the American military’s M16s as well as chassis plates, shafts (including those used in lacrosse sticks), gears, regulating valve components, and precision weapons like the M16 are also employed.

Due to its potential for aesthetic beauty, 7075 alloy is commonly employed in the manufacture of mold tools, particularly in the plastics industry.

Manufacturers and end users place a high emphasis on the 7075 aluminum’s lightweight and durability properties. It is extensively utilized in the automotive, aerospace, and aircraft industries because it is a sturdy, machinable aluminum alloy.

7075 aluminum is frequently used when making components having high stress that includes structural elements, gears, etc.

The grade 7075 is machinable and simple to work with. Aluminum alloy 7075 is not recommended for general welding. However, resistance welding the alloy might produce results that you find pleasing. The alloy’s inherent anti-corrosion qualities may be diminished using arc or gas welding.

Wrap Up

In the aerospace, maritime, and transportation sectors, where low weight and high stress resistance are key criteria, 7075-T6 aluminum is the material of choice. However, because of its well-balanced combination of qualities, it is widely used in many different sectors.